Wafer Head Self Drilling Screw

Material:Carbon C1022A Steel

Head Type:Wafer/Truss headhead

Thread Type:full thread, partial thread

Recess:Philips or cross recess

Surface Finish:Black/grey phosphate, White/yellow zinc plated ,Nickel

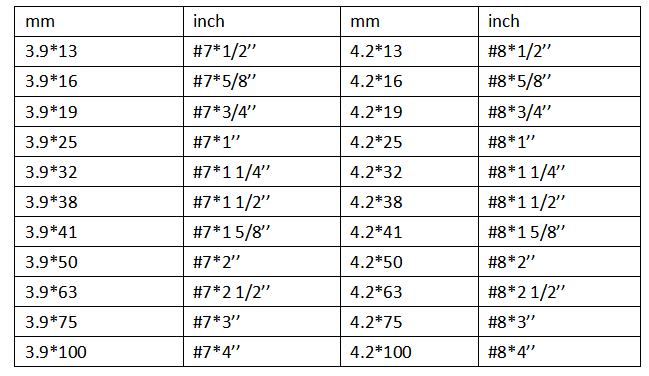

Diameter:7#(3.9mm),8#(4.2mm),10#(4.8mm)

Length:13mm-100mm

Point:Drill or sharp

Non-standard:OEM is available

Supply capacity:1200tons/month

Packing:Small box, bulk in carton or bags ,polybag or Customer request

Wafer head self-drilling screws are high-efficiency fasteners that provide self-drilling and anti-loosening functions, widely used in construction, machinery, and automotive industries.

Wafer self-drilling screws (also known as "washer-equipped self-drilling screws") are a special variation of the self-drilling screw. Their most distinctive feature is the integrated washer ("wasp") at the head, which automatically distributes pressure during tightening, resulting in a more secure connection and preventing loosening over long-term use. This design eliminates the need for additional flat or spring washers, improving construction efficiency and connection reliability.

The screw's front end has a drill-like structure, allowing for direct drilling, tapping, and tightening operations on materials such as steel and corrugated steel sheets, without the need for pre-drilling.

Common head types include hexagonal washer heads, round washer heads, and large flat washer heads, suitable for different tools and load requirements.

Common washer drill-drilling materials include galvanized carbon steel with blue-white zinc or yellow zinc, and phosphor black surface treatments.

We also offer stainless steel options (such as 304 and 316), suitable for humid or corrosive environments.

Main applications include: fixing corrugated steel sheets in steel structure buildings; connecting thin plates in prefabricated houses, fences, and lightweight partitions; assembling automotive body parts; and building projects such as curtain walls, sunrooms, and window screens.

However, it should be noted that wafer self-drilling screws are not suitable for direct connections between thick metals: the drill tip cannot penetrate high-hardness metals, which may lead to breakage or failure.

If 410 stainless steel is used, this material has high hardness and is suitable for drilling iron plates; 304/316 has strong corrosion resistance but is softer and is only suitable for thin plates (12mm).